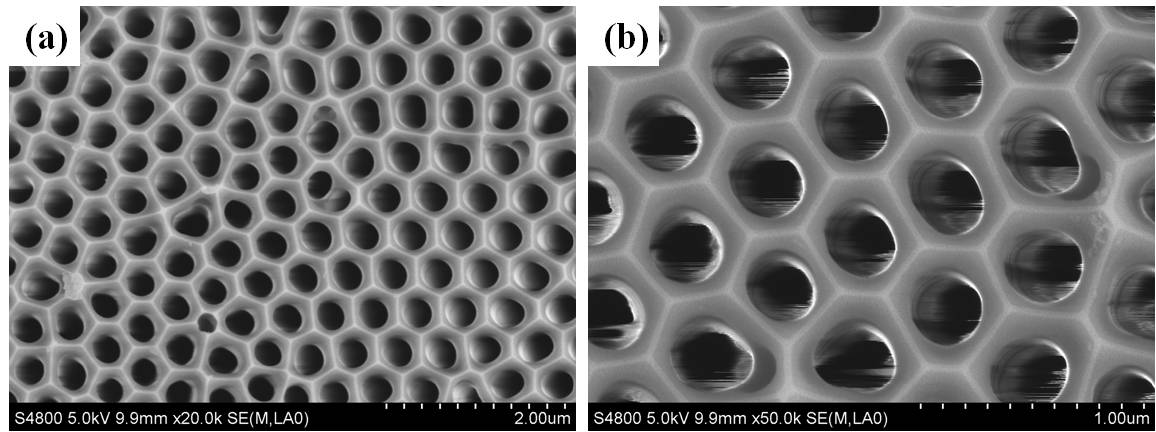

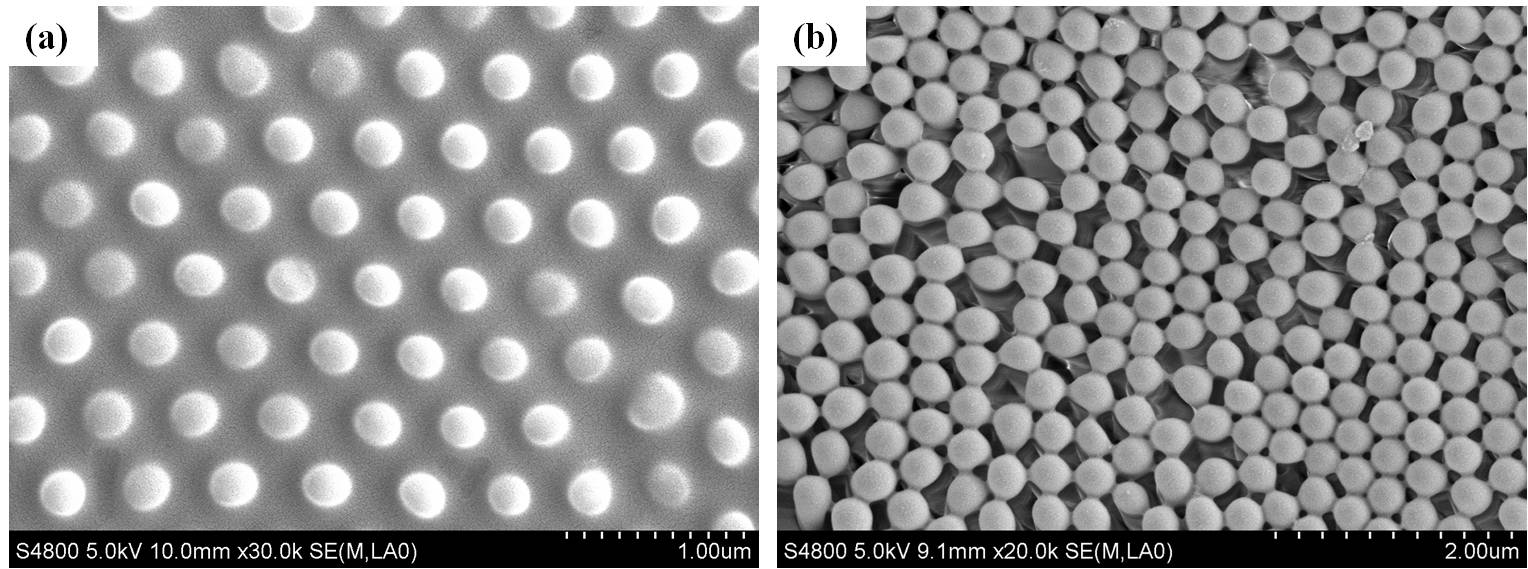

In our experiments, the porous anodic alumina templates were the master molds, which include structures with the diameter of 200nm and 350nm, respectively. The SEM images of the master molds are shown in Figure 3. The nano-hole arrays on the templates were uniform. Two different PDMS stamps were prepared via soft imprinting lithography to be as the soft stamp to fabricate the double-sided nanostrucutres.

Figure 3.

Porous anodic alumina templates: (a) the diameter is 200nm. (b) the diameter is 350nm. The soft double-sided nanopillar arrays were fabricated via twice soft-nanoimprint lithography as shown in Figure 4. The elastic PET film was the substrate. The large area of the nanopillars array was 3cm×3cm, which was determined by the master mold. The PET we used is transparent for visible light, so the PET double-sided nanopillars array could be used as optical device.

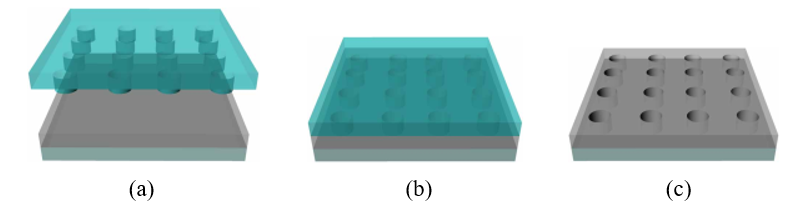

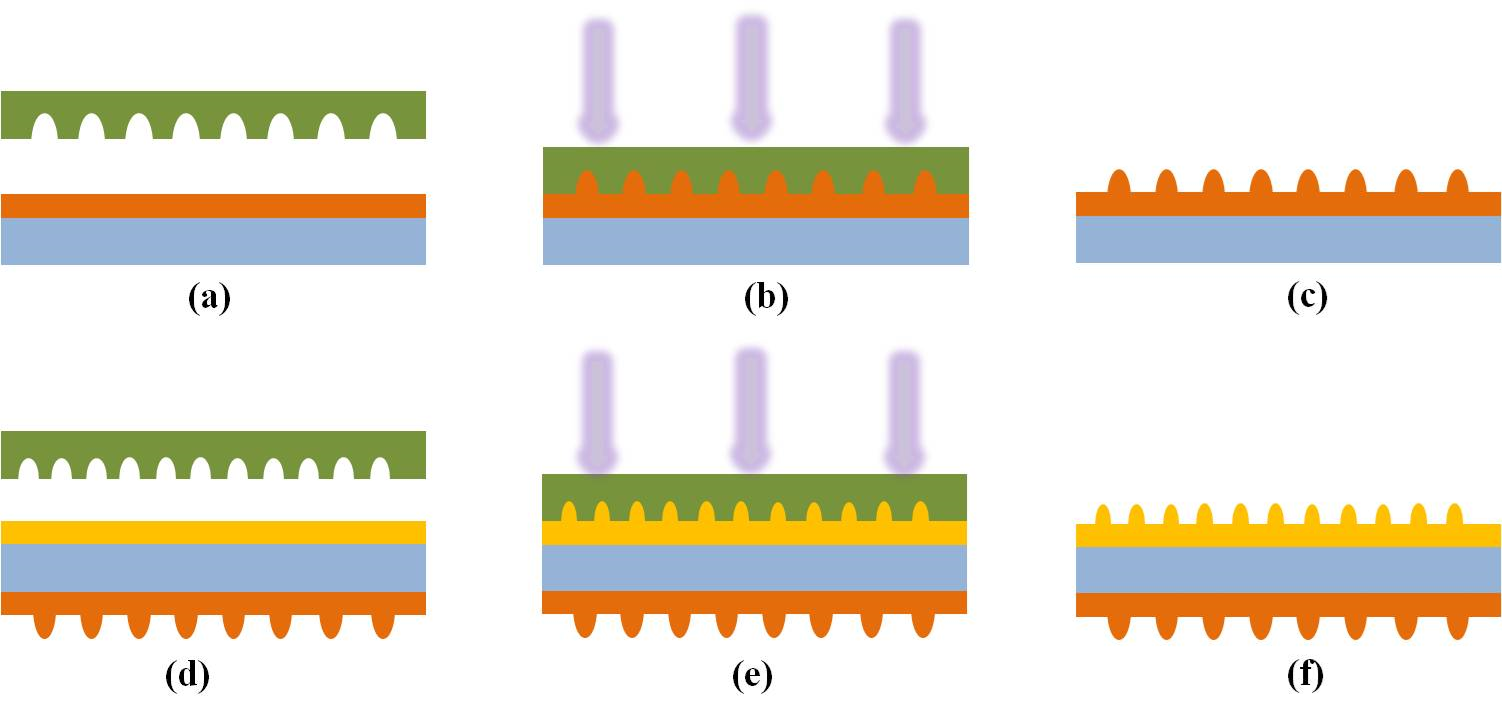

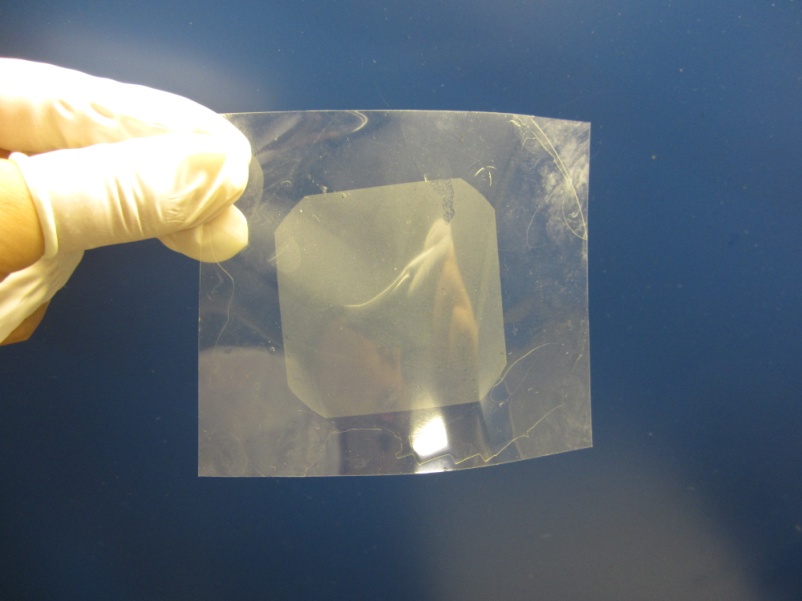

Figure 4.

The photo of the double-sided nanopillars array on the PET substrate. During the fabrication process, we first used the one PDMS stamp to fabricate the nanostructure on the one side of the PET substrate. The thiol-ene resist was spin-coated onto the surface of the substrate to form a 2μm thick film. Then the stamp was imprinted onto the resist film to make the resist fill into the relief structure. The resist could be cured to form cross-linked polymer under the UV light. Releasing the stamp, the nanopillars array with size of 200nm was achieved, as show in Figure 5(a).

In order to fabricate the nanostructure on another side, a thin PDMS protective film was coated onto the nanopillars array to protect the preparation structures. Because the PDMS film was soft and nonadhesion, it could be gently peeled off the nanostructures without any effects. The same thiol-ene resist was coated onto another side of the substrate via casting process. Because the resist is low viscosity, a uniform 3μm thin film was formed. The other stamp with diameter of 350nm was imprinted onto the film and cured under the UV light for 30 seconds. Releasing the stamp, we obtained the device with double-sided nanopillars array. And the nanopillar with size of 350nm was illustrated in Figure 5(b), which isn’t uniform due to the low performance of the imprint resist and low precision of fabrication process. In future experiments, we will improve the mask and imprint resist to optimize the experimental results.

The nanopillar arrays on the double-sided PET substrate were high-resolution, high uniform and high-precision. The nanopillars array with the diameter of 350nm arranged more densely. In this article, we fabricated nanopillars array with the different diameters. In addition, we could also use two soft stamps with the same nanostructures or completely different nanostructures, such as gratings on the side and nanoholes on another side.

Figure 5.

The SEM images of the double-sided nanostructure on the PET elastic substrate: (a) one sided nanopillars with the diameter of 200nm, (b) another sided nanopillars with the diameter of 350nm. The UV-curable soft-imprint lithography is very simple, even for fabricating the complicated double-sided nanostructures. The fabrication process is high efficiency, low-cost and high-resolution for inexpensive high-volume commercial production in the future.

As a new kind of quasi-3D nanostructure, the double-sided nanopillars have new capabilities to extend the applications field in optical and electronic devices. For example, in order to enhance the electrical properties, a metal layer was deposited onto the PET substrate. And the antireflection film was coated onto the nanostructures to increase the transmission. Therefore, the double-sided nanostructures have potential on the applications such as nanogenerator, sensor, absorber, and nano-antenna.